In a cost saving move C&L Rivet was recently contracted to eliminate material waste for a customer, due to the machining of a large “head to shank ratio”. The cold heading process can upset and or extrude material with virtually no material loss.

-

Fabricated Low Carbon Steel Delay Core for the Electronics Industry

Engineering of a Kovar Weld Stud for the Glass Seal Industry

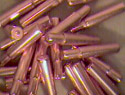

Cold Heading of a Large Headed Rivet in Brass for the Telecommunications Industry

-

Cold Heading of a Stainless Steel Adjusting Screw for the Water Sprinkler Industry

Cold Heading of a Brass Split Terminal Pin for the Electronic Connector Industry

Cold Heading of Automotive Power Seat Transmissions